FROM TRADITIONALTRADITIONAL

HANDCRAFTED

LATHE-TURNINGLATHE-TURNING

TO THE INVENTION

AND USE OF NEW

TECHNOLOGIES

Our latest generation lathes for making round jaws, square jaws, bezels, conicals, pins and screws.

GOLDSMITH TRADITION AND INNOVATION.

4.0 DIGITAL TRANSFORMATION

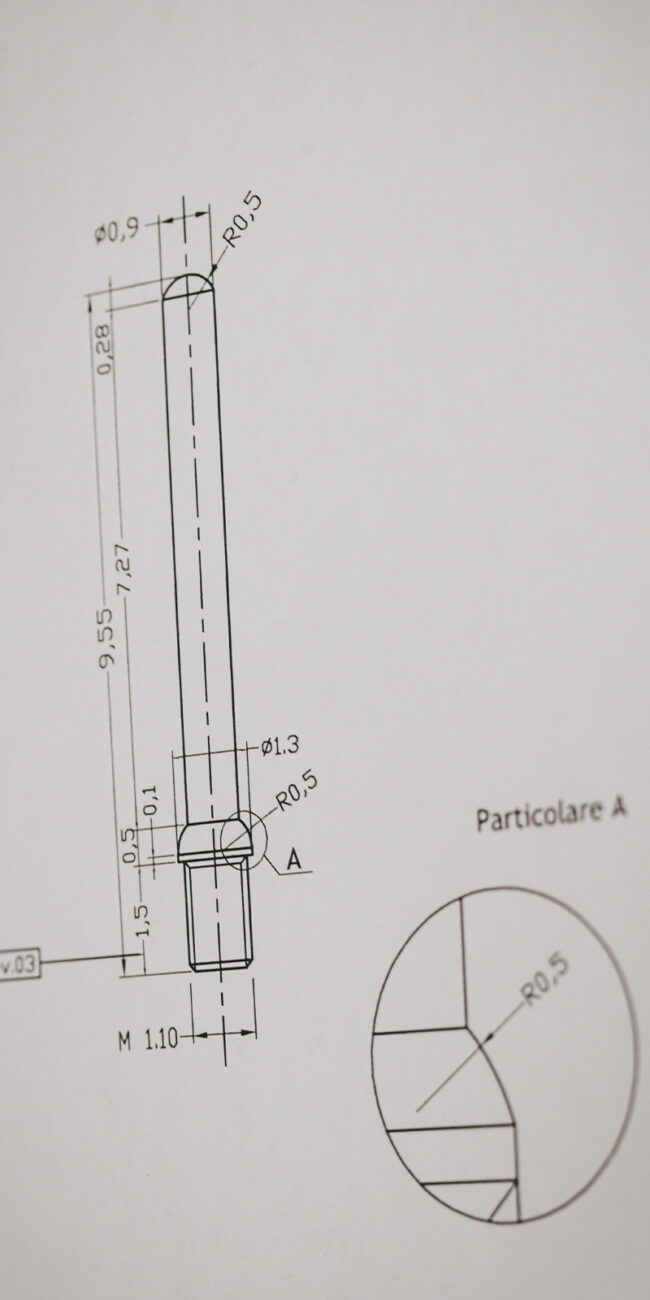

The birth of our projects take place starting from an initial plan, which is provided directly by the client himself. There is the possibility to deliver the work plan in two different formats: PDF or 3D printing. Inside of it there must be the all the estimates and dimensions of the product.

3D PRINTING

The first processing phase of each design involves rolling in cylinders, followed by drawing, which reduces the cross section of the wire with forced passes through dies that possess holes of decreasing order of diameter.

LAMINATION AND WIRE DRAWING

Turning is the removal of material until the desired dimension is achieved. Finally, with truncation, the excess part of the product is eliminated.

TURNING AND CUTTING OFF

GOLDSMITH TRADITION AND INNOVATION.

4.0 DIGITAL TRANSFORMATION

The birth of our projects take place starting from an initial plan, which is provided directly by the client himself. There is the possibility to deliver the work plan in two different formats: PDF or 3D printing. Inside of it there must be the all the estimates and dimensions of the product.

3D PRINTING

The first processing phase of each design involves rolling in cylinders, followed by drawing, which reduces the cross section of the wire with forced passes through dies that possess holes of decreasing order of diameter.

LAMINATION AND WIRE DRAWING

The lathe-turning involves removing excess material from the object, forming in this way a chip. After that, a few layers of the material are removed through the thread so that it reaches the desired size. Finally, through the parting the excess part of the product is cut off.

TURNING AND CUTTING OFF

OUR IDENTITY

For over 40 years D. M. Semilavorati srl has been the leader in the goldsmith craft sector for competence, transparency and for its considerable experience in the production of semi-finished products, featuring the help of the latest generation 4.0 technology.

Since 1982, the year the company was founded, we have set to ourselves the goal of maintaining the high level of quality in the production of each semi-finished product.

The processing phases start from the rolling process and then move on to the lathe-turning step, where the semi-finished products are established and matched with the original project.

All the steps of creation are fundamental for the achievement of the final result, for which it must be able to meet all the criteria the market establishes and the needs of each customer.

The present and the future of our company lie upon the values that the goldsmith tradition from Valenza gives as a legacy to today's artists and to the technologies of the sector that facilitate our daily productions.

Our range of services is constantly being updated and enriched every day to adapt to new lines and market developments in the goldsmith's craft sector, thanks to the introduction of high-tech CNC machines that have perfected the production of small parts - screws, hinges, taps, pins - for the watch and jewellery .

Each creation has different patterns and dimensions, aimed at improving the quality of the product and our service in its wholeness.

The treated golden colors include all the shades: 2N,3N, 5N. In addition to the Silver, Palladium Gold is also one of the most used material.

EXPERIENCE AND TALENT AT THE SERVICE

OF GOLDSMITH CRATMANSHIP.

THE PROJECT, THE FINISHED MODEL AND QUALITY CONTROL

Our semi-finished products represent the essence of a journey that is born together with your trust: with loyalty and professionalism we give life to an authentic and alive product, entirely customized according to your needs. Once the work is done, the object goes through an accurate quality control: each batch in fact is inspected 3 times during each single production phase and accompanied by a scrupulous, conscientious selection of semi-finished products through special magnifying glasses. The check phase is completed with a final control of the measurements using the "profile viewer": this allows us to ensure that the measures perfectly match the dimensions of the original model. If the product is in compliant with the expected standards, we proceed to deliver the final item.

ASSISTANCE AND CUSTOMER CARE SERVICE

We want to offer the best service ever, as more loyal as possible to its nature and tradition; for this reason, we wish every customer to perceive our company as present partner and very attentive towards their needs. Our daily commitment wants to achieve clarity and transparency so as to allow the birth of a strong and lasting bond, filled with perseverance and professionalism, which through our assistance staff conveys the values that have always distinguished our company.

SCHEDULED DELIVERY

We care about the relationship with our clients and their necessities: for this reason the commissioned works respect the delivery times previously agreed, keeping it on time, both for the items in the catalogue and for the customized requests.